The Bottleneck in Modern Failure Analysis

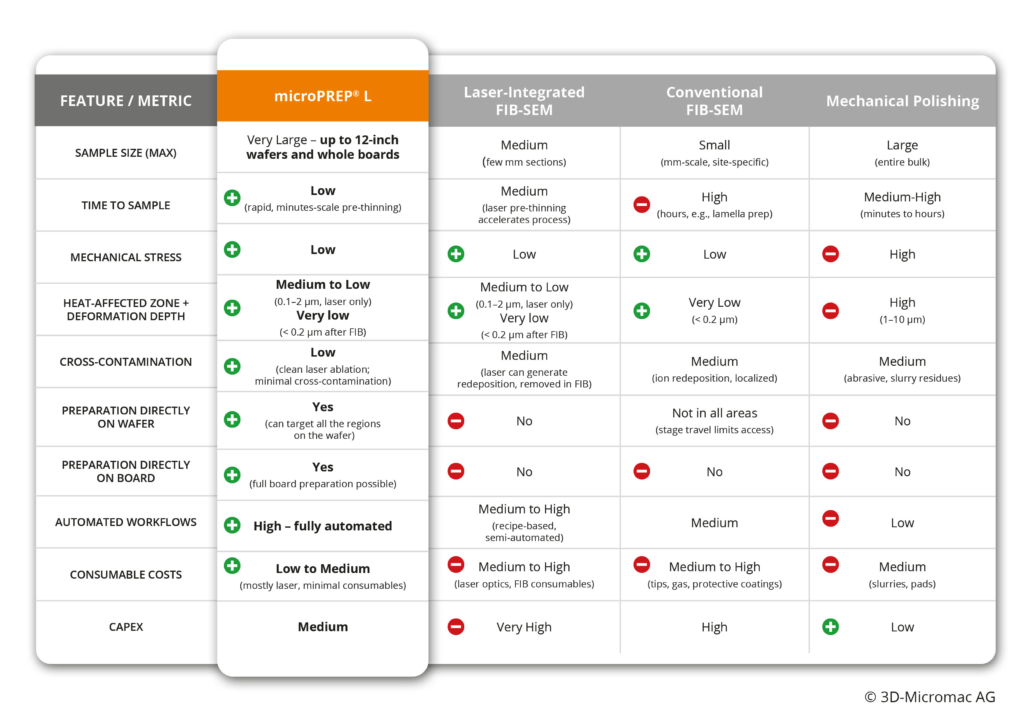

Mechanical polishing can induce stress and compromise the integrity of the sample. Conventional FIB milling is limited by ablation rate, sample size, operating cost, and the need for expert operators. Hybrid “laser+FIB” platforms combine functions but introduce capacity bottlenecks and particle contamination.

A Dedicated, Scalable Alternative

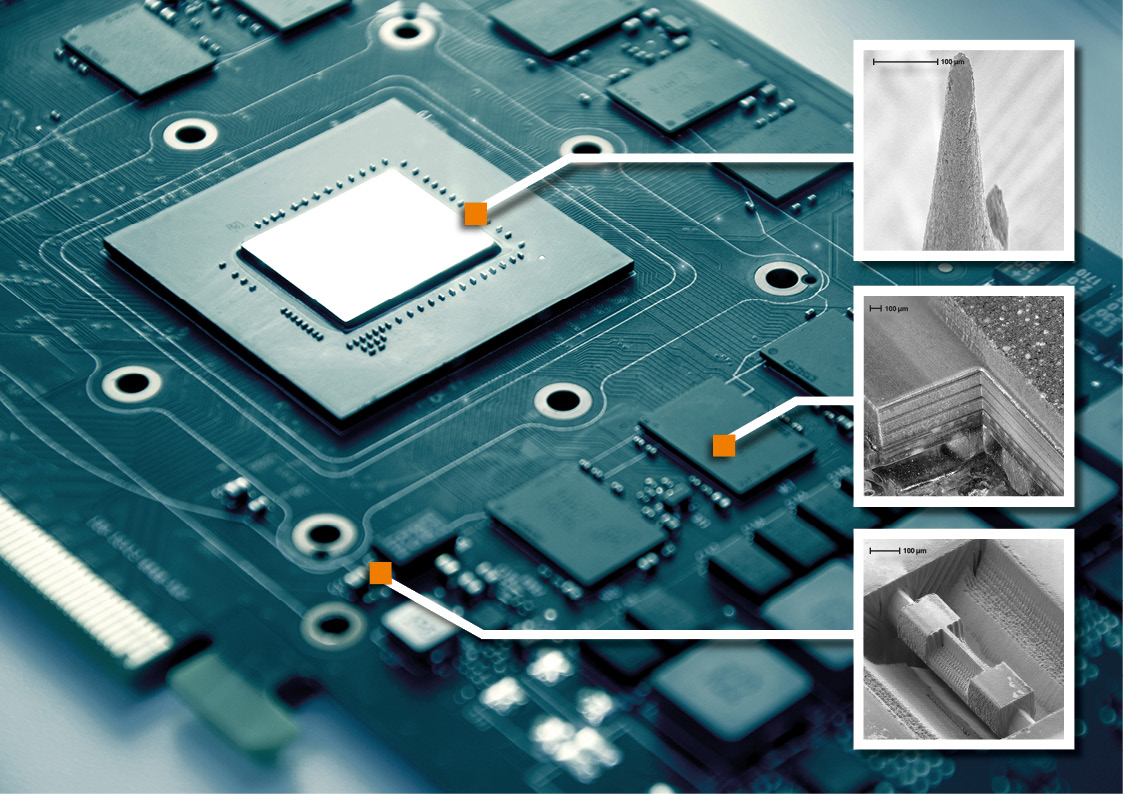

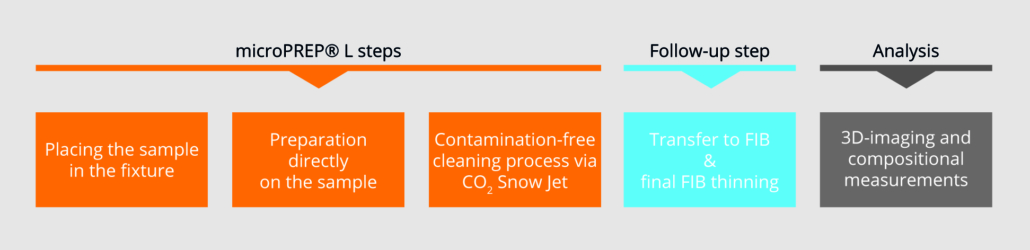

microPREP L is a standalone laser micromachining platform for fast, precise, and reproducible material removal—on large and complex assemblies, such as advanced semiconductor packages, printed circuit boards, and entire 12-inch (300 mm) wafers. By enabling system-level preparation without cutting the sample into pieces, microPREP L preserves device integrity and accelerates the localization of failures.

Key Benefits

-

Prepare multiple samples

on a single wafer or board in one workflow -

Micrometer-level targeting

with real-time depth sensing -

Offload bulk removal

and optimize downstream FIB/SEM tools -

Automation-ready

for high throughput and repeatability