microPREP® L

The microPREP® L is your tool for laser-based sample preparation – especially when operating in a fab environment.

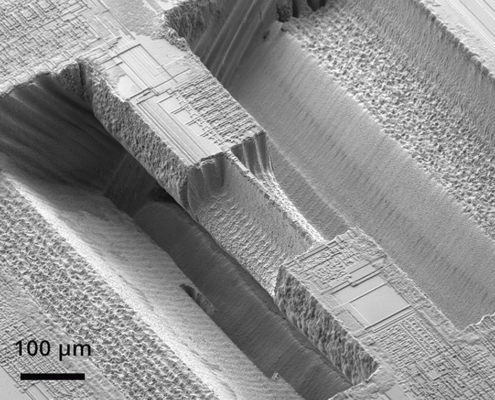

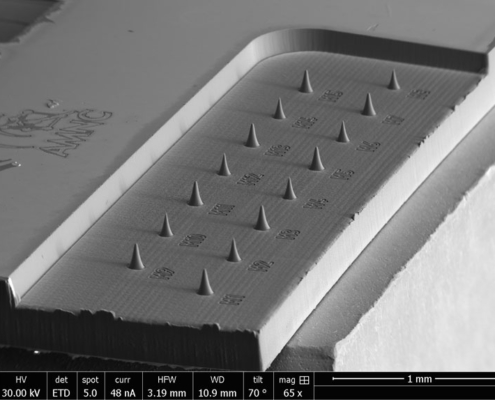

The primary advantages of microPREP L are its unmatched scalability in terms of sample size, high throughput and precision, and automation-ready workflows. The system is designed to support sample sizes up to whole 12-inch (300-mm) wafers and system-level boards. It delivers productivity gains for failure analysis, process development, and quality assurance in the semiconductor and electronics industries. Multiple samples can be prepared at different locations on wafers or system-level boards within a single workflow, without process restarts.

By supporting system-level preparation without cutting up the sample into smaller pieces, this platform helps preserve device integrity, thereby accelerating failure localization and analysis. These capabilities also enable failure analysis to be extended beyond the lab and into fab environments, where rapid root-cause analysis is critical to improving yield and uptime.

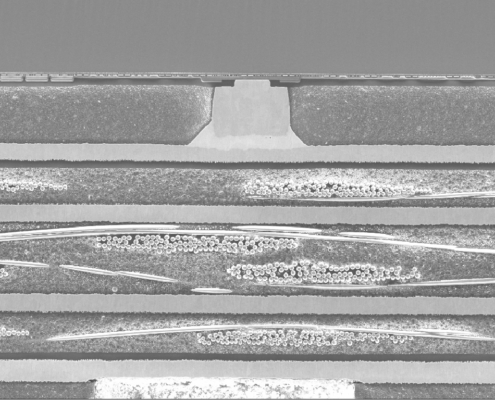

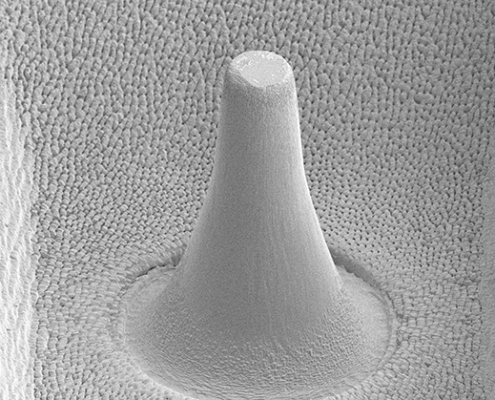

microPREP L can ablate metals, semiconductors, ceramics, polymers, and compound materials. It creates new vistas for material and process development and failure analysis.